What is the manufacturing process?

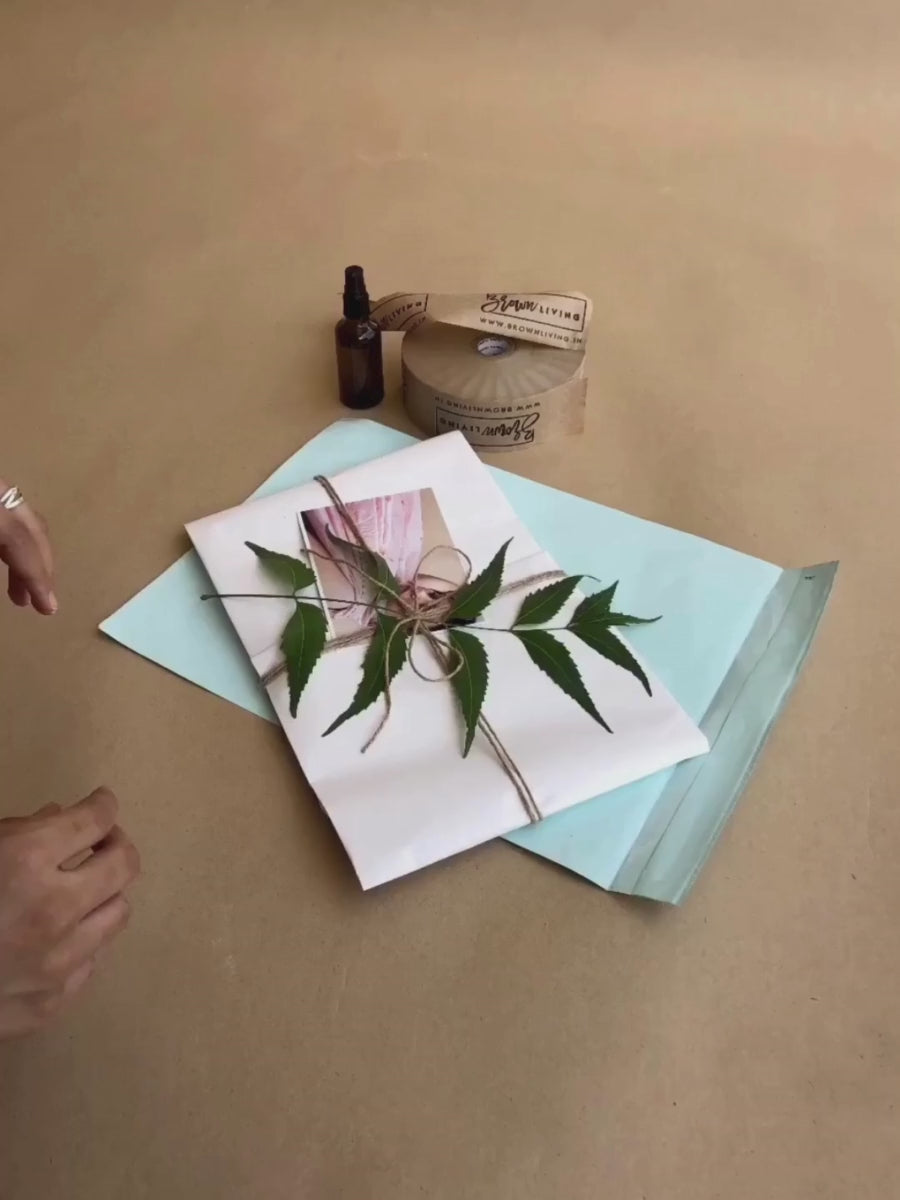

Fabric Sourcing – Handwoven fabrics are procured from local looms in Assam, supporting weaving communities. Botanical Foraging – Discarded flowers, leaves, and plant waste are collected from temples, markets, and households. Preparation – The foraged materials are sorted, cleaned, and made ready for use in dyeing and printing. Eco-Printing & Natural Dyeing – Botanicals are transferred onto fabrics using traditional techniques, creating unique, nature-inspired patterns without chemicals or synthetic dyes. Zero-Waste Approach – Residual plant matter is composted, ensuring nothing goes to waste. Cutting & Stitching – Fabrics are tailored into garments and accessories by skilled women artisans. Finishing & Quality Check – Each piece is inspected for durability, comfort, and design excellence. Packaging – Products are packed in eco-friendly materials, completing a fully sustainable cycle.

What are the ingredients/materials you use?

Econic works with a unique mix of natural, sustainable, and locally sourced materials. Our base fabrics are primarily handwoven cotton and eri silk from Assam, chosen for their breathability, durability, and connection to heritage weaving traditions. For colors and patterns, we rely on botanical ingredients—discarded flowers, leaves, seeds, barks, roots, and vegetable or fruit peels collected from temples, markets, and households. These natural elements are used in eco-printing and natural dyeing, replacing synthetic chemicals with plant-based alternatives that are safe for artisans and the environment. We also integrate organic mordants such as alum, iron, or natural tannins to fix colors in an eco-conscious way. Every leftover botanical residue is composted, reinforcing our zero-waste approach. Even our packaging materials are eco-friendly, made with recycled or biodegradable options, ensuring sustainability at every step.

How do you source your raw materials/ ingredients?

At Econic, sourcing begins with a focus on local, ethical, and sustainable practices. Our base fabrics, primarily handwoven cotton and eri silk (ahimsa silk) are procured directly from weaving clusters in Assam, ensuring fair wages and continued livelihood for artisans. For natural dyeing and eco-printing, we collect discarded flowers, leaves, and plant waste from temples, local markets, juice shops, and households, giving new life to materials that would otherwise become waste. Whenever additional dyeing ingredients are needed, we rely on locally available roots, seeds, and barks, purchased from small farmers and traditional suppliers. To maintain eco-consciousness, we avoid synthetic chemicals, instead using safe, natural mordants like alum, iron, and tannins in minimal quantities. In this way, our sourcing process strengthens local ecosystems, supports communities, and keeps sustainability at the core.

During its life and beyond, can your products be repurposed or composted at home?

Econic products are designed for sustainability throughout their lifecycle. Our handwoven cotton and eri silk fabrics are fully biodegradable: cotton can decompose in 1–5 months under optimal composting conditions, while eri silk, being a natural protein fiber, also breaks down over time, especially when shredded. All our garments use wooden buttons as closures, ensuring they are fully compostable without synthetic components. Beyond composting, products can be repurposed into quilts, cushion covers, table runners, or DIY craft materials, extending their life and minimizing waste. By using discarded plant materials and zero-waste practices in production, Econic ensures that both the creation and end-of-life of our textiles remain eco-conscious, supporting artisans, preserving traditional crafts, and promoting a circular, sustainable approach to fashion.